Technology advancements enable innovative aerospace product creation. One breakthrough, diffusion bonding, joins dissimilar metals in manufacturing. Design engineers favor it for process control and compatibility. Explore diffusion bonding intricacies, applications, and its competitive edge when partnering with PVA TePla. Unlike traditional welding, diffusion bonding solidly intermixes metallic surfaces without melting. The result is a robust and ductile bond with minimal stress. It is ideal for high-strength, reliable applications at elevated temperatures.

Potential Applications of Diffusion Bonding in Aerospace Manufacturing

Diffusion bonding is gaining popularity in the aerospace industry for connecting different metals. It offers advantages like weight reduction and improved fuel efficiency. Bonding titanium to iron-nickel alloys, titanium alloys to stainless steel, or even aluminum to other metals is remarkable. However, a deep understanding of the interface and its impact on chemical and thermo-mechanical properties is crucial for harnessing diffusion bonding’s potential in aerospace.

The Role of Expert Partners in the Industry

Diffusion bonding offers a multitude of possibilities beyond simply joining dissimilar metals. One such exciting application is conformal cooling, where layers of sheet metal with intricate channel and microchannel structures are fused together. By implementing this process, cooling systems in aerospace can achieve enhanced efficiency through a more uniform distribution of cooling. Moreover, the utilization of this process in conformal cooling has the potential to reduce weight and cost, making it a compelling choice over traditional cooling systems.

The Promising Influence of Diffusion Bonding

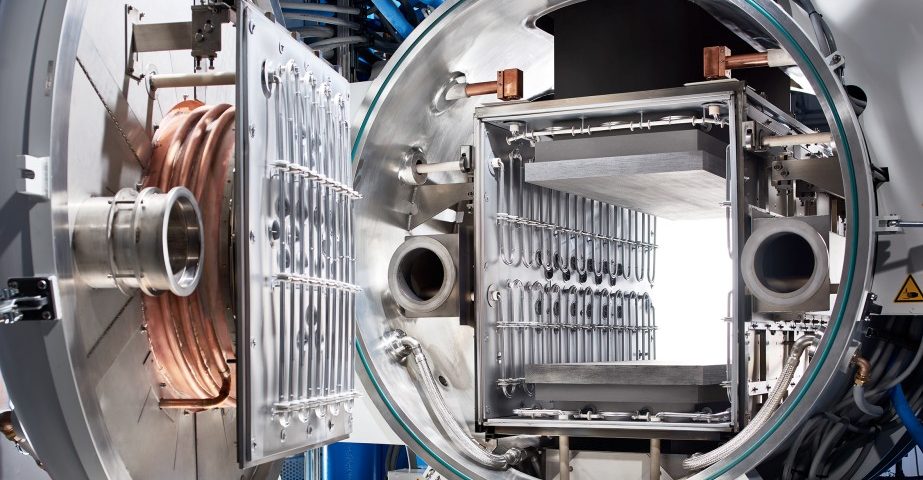

One of the significant advances in diffusion bonding technology is the development of high vacuum hot presses. These presses allow for superior pressure control and rapid cooling systems, improving the bond, increasing yields, and significantly decreasing cycle time. These advances have made the process easier and more efficient, making it a more viable option for aerospace manufacturers. Nevertheless, it remains crucial to collaborate with industry experts like PVA TePla to fine-tune the process for specific applications and unlock its full potential. This strategic partnership ensures optimization and maximizes the myriad benefits that can be achieved.

Significance of Continuous Research and Advancements in the Aerospace Industry

Diffusion bonding is an incredibly exciting and cutting-edge development in the aerospace industry. It holds immense potential for joining dissimilar metals and enhancing cooling systems. While the technology has made significant progress, it still requires the expertise of specialists to optimize the process for specific applications. By collaborating with renowned experts like PVA TePla, manufacturers in the aerospace industry can gain a significant competitive edge in part design and production ramp-up. As technology advances, we eagerly anticipate the new applications and groundbreaking innovations that will emerge from the fascinating science of diffusion bonding.