Effective wastewater treatment is paramount in any industry. The food processing sector comes with its own unique set of challenges. The problem for wastewater treatment is that no fluid processing or filtration system remains static. Treatment conditions continually change due to variable factors such as pressure, particle size, solids loading and even the presence of sticky biologicals.

Fortunately, a separation technology designed to tolerate variability – automatic scraper strainers – can be used when reliable, economic, low-maintenance water treatment is necessary. This blog post delves into how automatic scraper strainers can revolutionize the process when they are used after clarifiers and before further processing.

Understanding Food Processor Wastewater Treatment

The food processor industry generates a significant amount of wastewater characterized by organic matter, suspended solids, grease, fats, and chemical residues. The need for efficient wastewater treatment cannot be overstated.

The Food Processor Industry and Wastewater

From meat packing to vegetable processing, every segment of the food processor industry contributes to wastewater. Understanding these sectors and the characteristics of their wastewater is key to effective treatment.

Challenges in Wastewater Treatment

Food processor wastewater treatment is often plagued by several challenges:

- Accumulation of solids and debris

- Algae growth and fouling

- Clogging of equipment and pipelines

- Presence of contaminants

Explore the role of automatic scraper strainers in tackling these unique wastewater treatment challenges within the food processing industry. Delve into the characteristics of wastewater the food processor industry generates and the need for efficient treatment strategies.

Automatic Scraper Strainers: The Game Changer

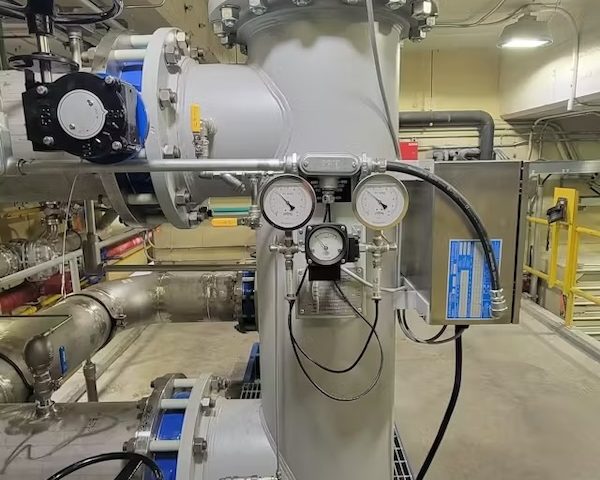

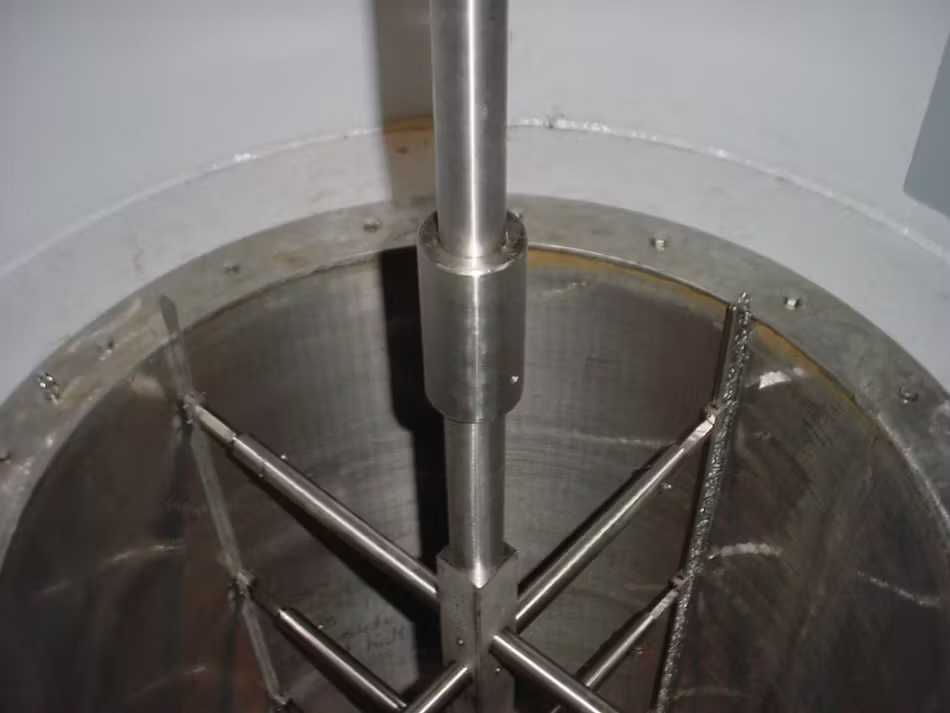

Learn about the groundbreaking functionality of these innovative devices and their profound impact on enhancing treatment efficiency. Modern automatic scraper strainers like Acme’s are meticulously engineered to withstand unexpected challenges. Acme’s motorized unit is purpose-built to eliminate both large and small suspended solids from wastewater consistently. This is achieved through a meticulously designed spring-loaded blade and brush system, expertly managed by a fully automated control system.

Learn about the groundbreaking functionality of these innovative devices and their profound impact on enhancing treatment efficiency. Modern automatic scraper strainers like Acme’s are meticulously engineered to withstand unexpected challenges. Acme’s motorized unit is purpose-built to eliminate both large and small suspended solids from wastewater consistently. This is achieved through a meticulously designed spring-loaded blade and brush system, expertly managed by a fully automated control system.

Tackling Accumulation and Algae Growth

Explore the methods utilized by automatic scraper strainers to address issues related to accumulation and algae growth effectively. When it comes to wastewater, conventional automatic backwash strainers face a unique challenge posed by adhesive biologicals such as algae. These biologicals not only foster the presence of other contaminants like scum, grease, sludge, and foam, but they also gradually diminish the strainer’s usable open area. Over time, conventional automatic backwash strainers will lose effectiveness and require cleaning to restore their proper function.

Biofouling Prevention Strategies

Uncover the benefits of automatic scraper strainers in combating biofouling, a prevalent issue in wastewater treatment. By employing scraper brushes, these strainers efficiently eliminate particulates and solids from wedge-wire slots, averting clogs and fouling. This approach guarantees comprehensive cleaning and proves particularly effective in mitigating organic matter biofouling.

The Synergistic Impact of Scraper Strainers on Food Processor Wastewater Treatment

Companies must adapt to changing wastewater treatment conditions influenced by production and seasonal variations. To meet compliance requirements and safeguard downstream equipment consistently, it is crucial to employ flexible and reliable technology. Automatic scraper strainers are purpose-built for these challenges, gracefully handling surprises and variability while minimizing maintenance needs.

Discover more for a comprehensive exploration of these topics as we delve deeper into the revolutionizing role of automatic scraper strainers in food processor wastewater treatment!

For more information, visit Acme Engineering Products Inc.